Write a well-structured, comprehensive and (ISO) EN 12100 compliant machinery Risk Assessment

Export in PDF and Excel formats

yInterlock helps engineers and product designers write effective risk assessments compliant with the latest guidelines of ISO 12100 standard.

The application’s 9-stage process will help you:

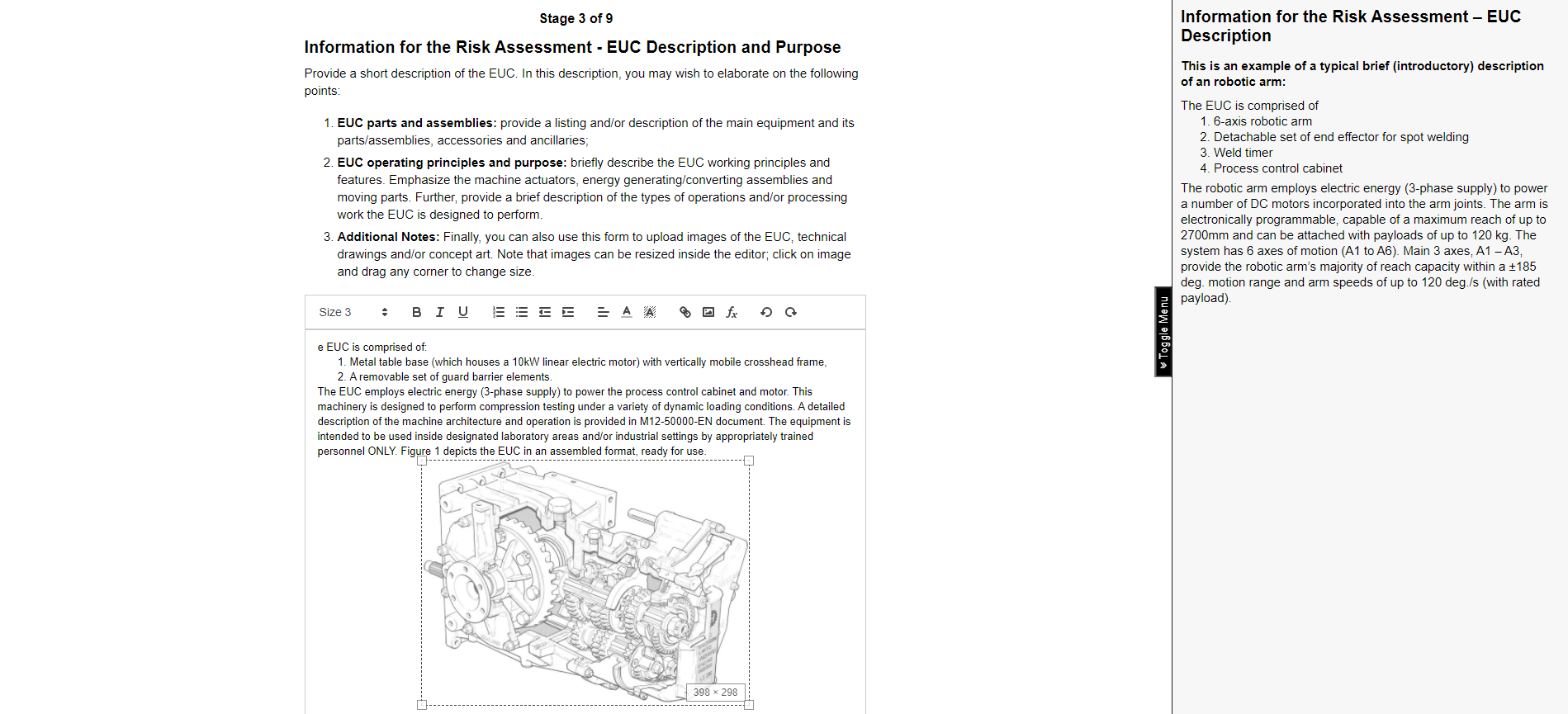

- Identify all relevant sources of information for your risk assessment

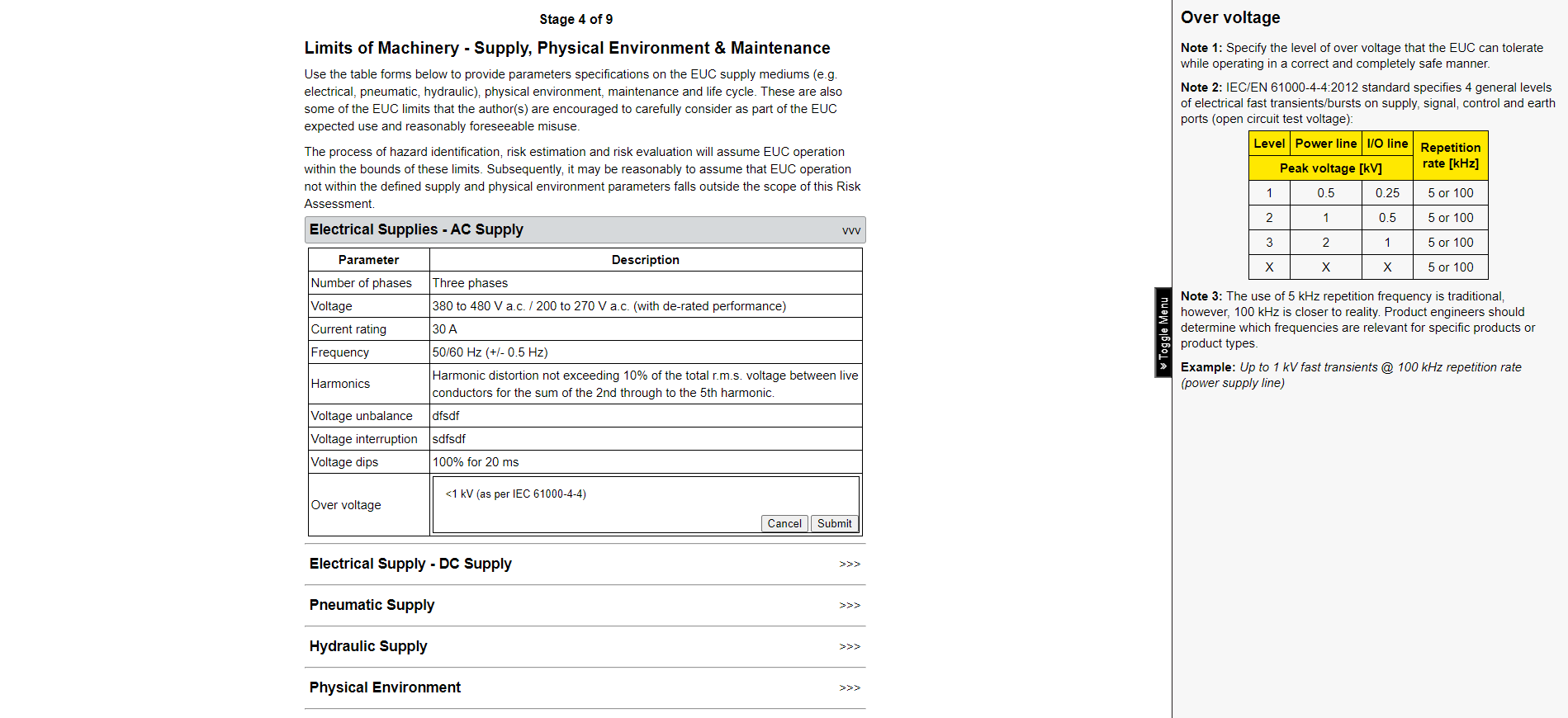

- Establish all the limits of your machinery (physical environment, supply, operating modes, etc.)

- Identify all reasonably foreseeable hazards, hazardous situations and/or hazardous events

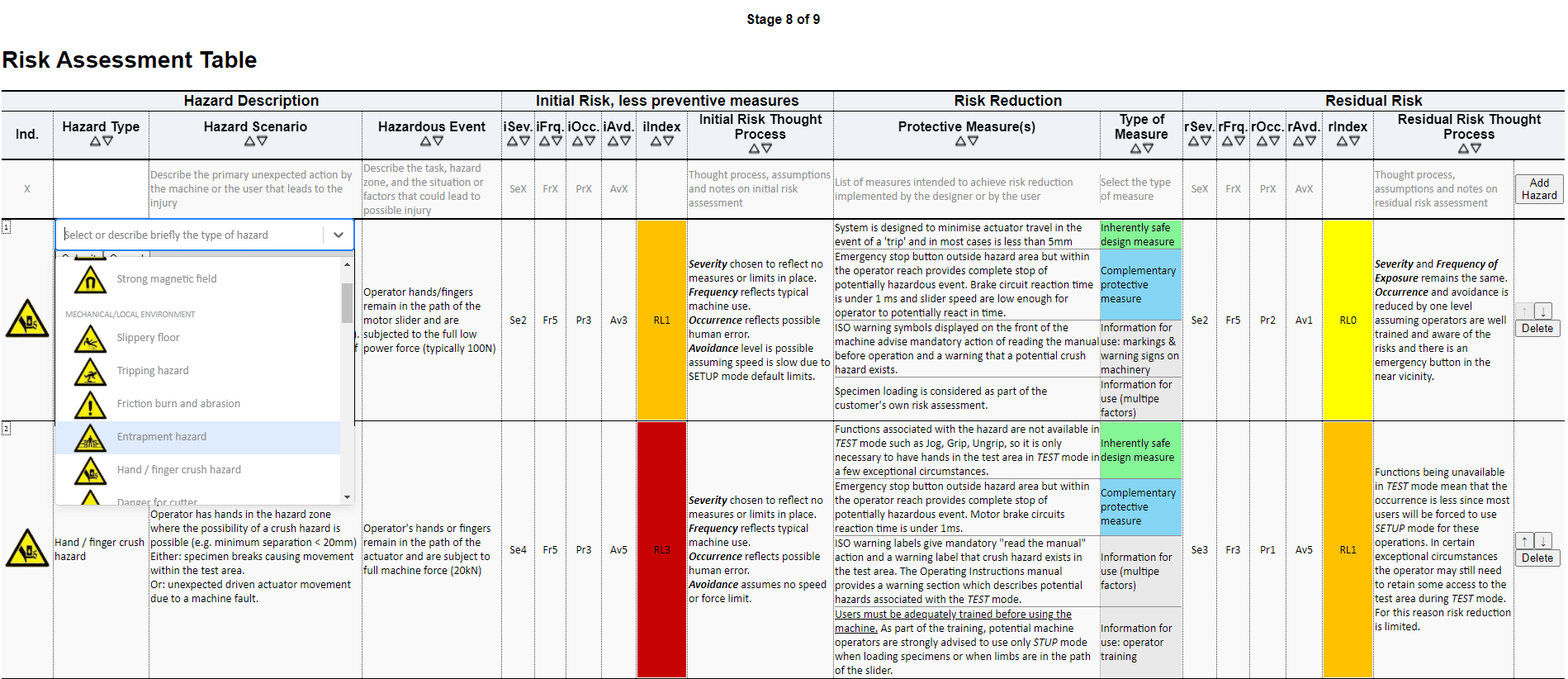

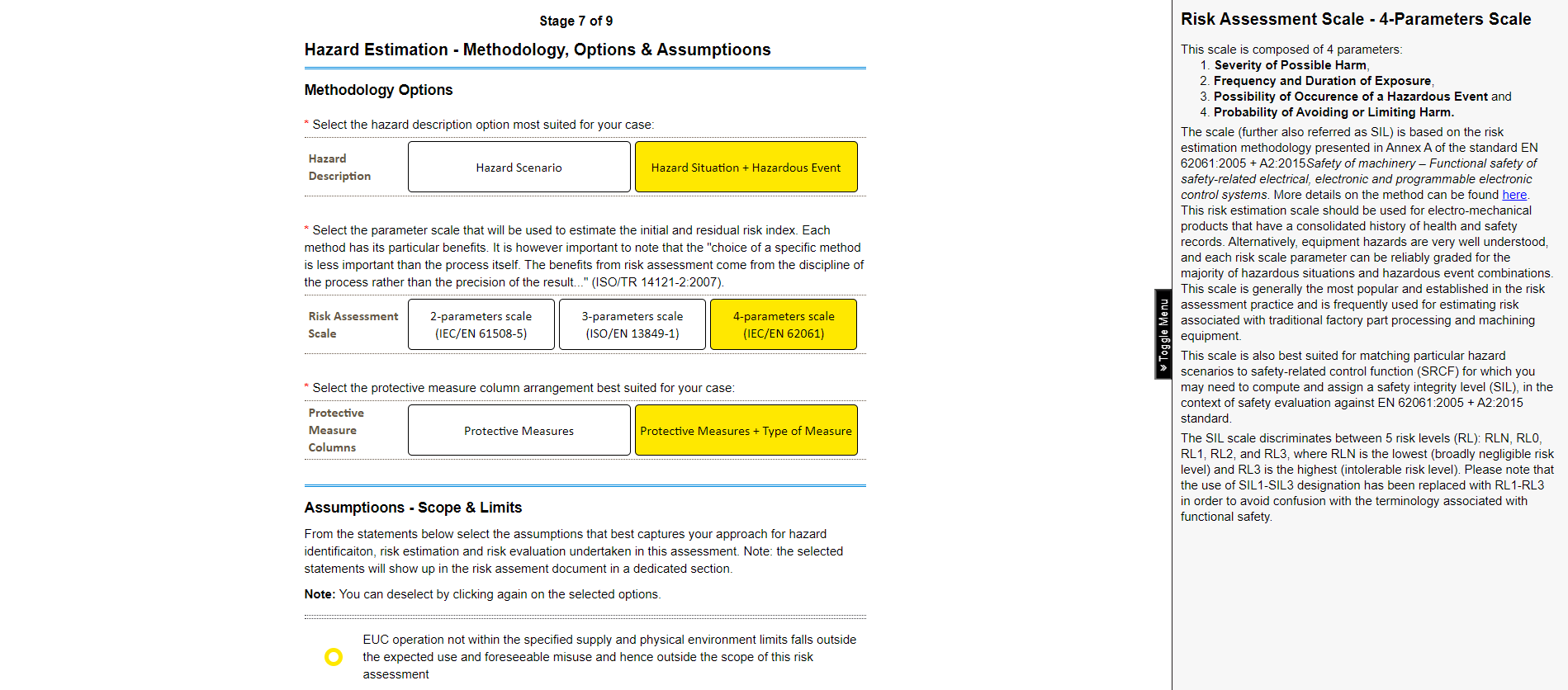

- Select the most appropriate risk estimation scale and assumptions for quantifying the risk level

- Add protective measures for each hazard and quantify their effectiveness

- Export your assessment in a well designed and printer-friendly PDF or Excel formats

ISO 12100 compliant

Purposefully designed to provide strong compliance with ISO 12100 (EU), ANSI B11.0 (North America) standard guidelines and ISO/TR 14121-2 report

Export in Excel format

yInterlock enables you to export your risk assessment document in Microsoft Excel, carefully formatted for printing

CE Compliant

Designed to meet EU machinery directive standards (IEC) EN 60204-1:2018, (IEC) EN/UL 61010-1:2019, (ISO) EN 13849-1:2015 and IEC 62061:2005 + A2:2015

Extensive tips and examples

Every step of the process is supplanted with examples and explanatory articles designed to help users

Export in PDF format

Save and resume your risk assessment at any point; preview and download in PDF format (printer friendly)

Completely FREE

This application is currently free to use through the entire process, including the PDF and Excel export option

Download a Machinery Risk Assessment example generated by this application. This is how your next machinery risk assessment can look like.

Please note that this risk assessment is based on a fictional piece of equipment with fictional hazards. Any resemblence to a real machinery is by pure coincedence

A journey of a thousand miles begins with a single step risk assessment

Risk assessment is probably the first and one of the most important compliance documents in the initial stages of machinery design and CE marking process. Yet, more often than not, this report receives least amount of engineering attention or the activity is left due at the very end. The consequences speak for themselves: hazards and safety deficiencies identified in later stages of development or in the field are exponentially harder and costlier to fix. Risk assessment failures can also lead to human injuries, loss of reputation and litigations or worse (like in this case, or this case).

Do not leave the quality of this document to chance. Use yInterlock's intuitive and simple steps to create an effective risk assessment that identifies hazards early in the desing stage.

Risk assessments are also hard to get right, especially for complex machinery. This discovery and reporting activity requires a good level of understanding of the:

- machinery use and reasonably foreseeable misuse,

- risk assessment standards such as ISO 12100-1 and ANSI B11.0,

- general machinery/functional safety standards,

yInterlock's step-by-step guided articles and practical examples will help inexperieced users to understand and navigate the complex risk assessment process.

Loading...